Tunnel Dilapidation Survey

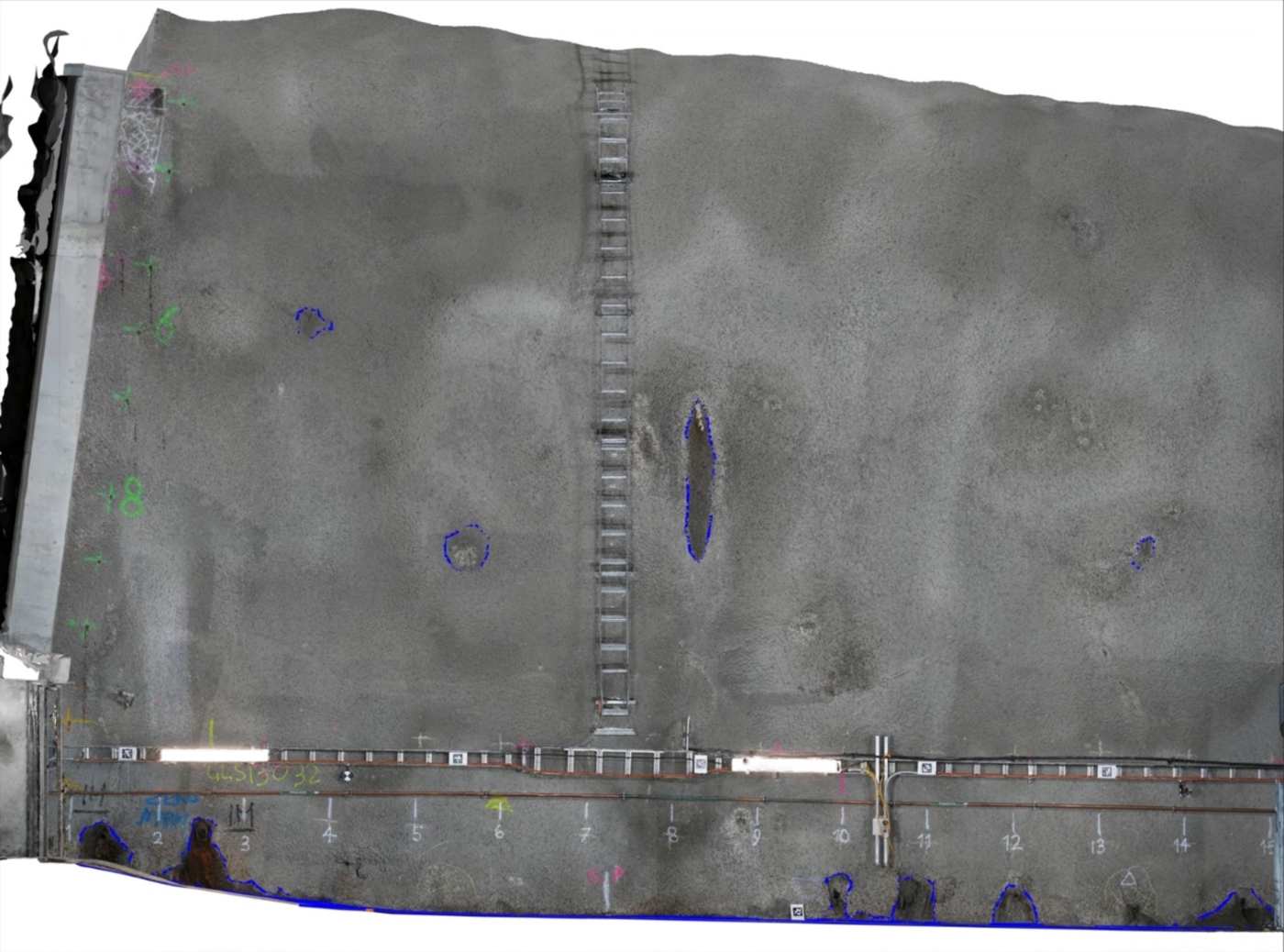

defect mapping of tunnel for pre-construction dilapidation survey using photogrammetry modelling and terrestrial laser scanning

PROJECT OVERVIEW

Construction work was to occur below a 75m portion of tunnel and was planned to use Tunnel Boring Machines (TBMs). The construction contractors were required to monitor the integrity of the 75m long portion of existing tunnel to ensure the TBMs were not negatively impacting its integrity. A tunnel dilapidation survey would precisely map any defects, seepage and cracks before, during and at the end of construction. Diospatial was engaged to provide a high detail and precise dilapidation survey of the 75m long tunnel.

Project Scope

DIOSPATIAL SOLUTION

Diospatial developed a geospatial solution that utilized terrestrial laser scanning and photogrammetry. The laser scanning was used for precise capture of the spatial geometry, including cracks. The photogrammetry modelling was used to provide visualisation of the surficial condition of the tunnel.

Terrestrial laser scanning was carried out twice throughout the tunnel to act as a double baseline survey before the TBMs passed through. A 1″ total station was used to achieve a high accuracy survey output. A survey control network was established and will be used for the subsequent surveys to ensure an accurate comparison can be made throughout the construction timeline.

The terrestrial laser scanning survey achieved an accuracy of 3-5mm, meaning any changes, like shotcrete spalling, delaminating or changes in the tunnel profile, that are greater than 5mm in magnitude will be evident.

Terrestrial Laser Scanning achieved a survey accuracy of 3-5mm, enabling very precise detection of changes throughout the construction timeline.

High resolution images were captured of the tunnel using extensive artificial lighting and processed in photogrammetry software to produce a 3D digital twin. The geolocated digital twin provided rich visualisation of the tunnels and was used by a Diospatial Data Technician to map surficial defects including cracks and seepage. This was then used to produce elevation and plan view orthographic renders used to produce the PDF defect maps.

The photogrammetry model achieved a resolution of 1mm/pixel.

The complete geospatial data set was also hosted on a web-based 3D GIS platform, Pointerra. This allowed project stakeholders to visualize, interrogate and download data without the need for specialist software or powerful computing hardware.