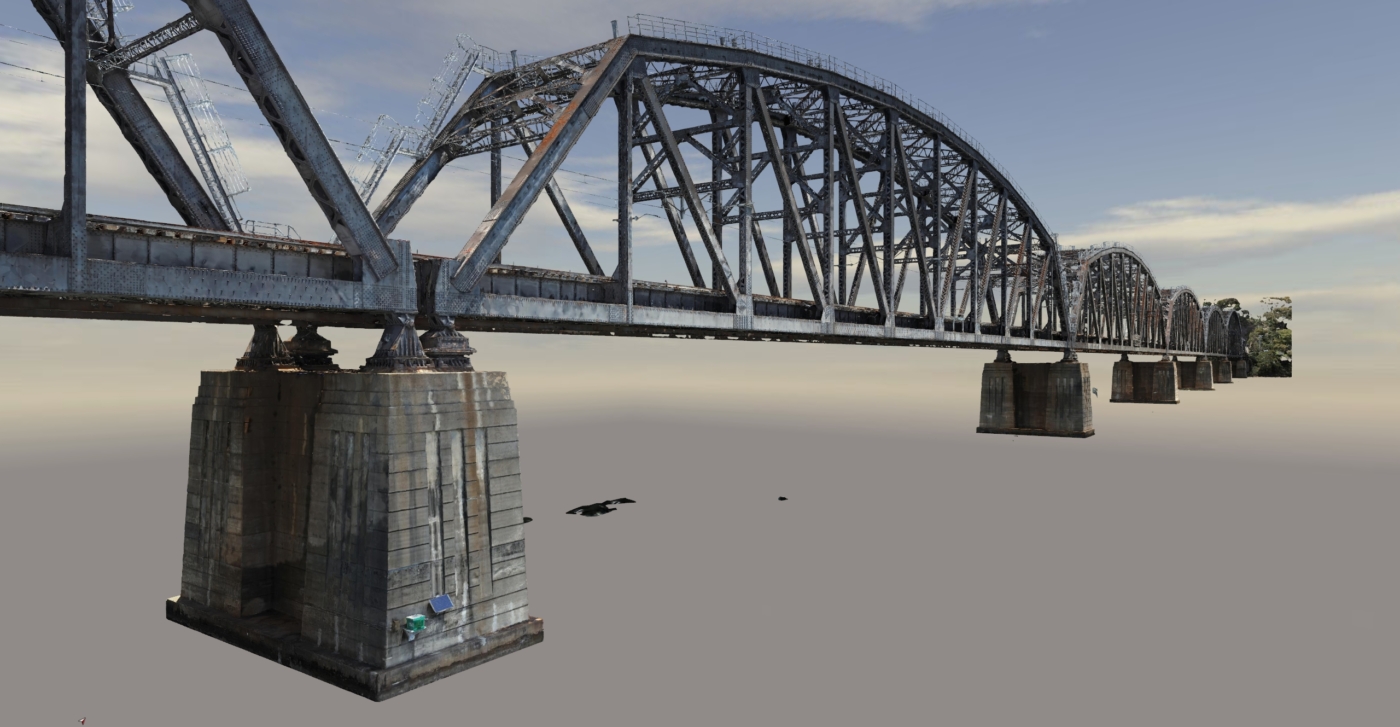

High Detail Digital Twin of Rail Bridge

Reality modelling of rail bridge to assist with the planning and design of maintenance and bridge refurbishment works.

PROJECT OVERVIEW

Planning was required for the extensive refurbishment of the ~900m rail bridge. Inspection and planning of the maintenance works was required before works could begin.

Access to the bridge was only available during infrequent rail possession periods, and there were limited safe places on the bridge to complete a thorough inspection. As a result, working at heights would be required to complete a full inspection.

A high detail digital twin would reduce the reliance on rail possession periods, and allow consulting engineers to inspect and access the bridge as needed from the ease of their desk.

Project Scope

DIOSPATIAL SOLUTION

Diospatial was engaged to capture and produce a spatially accurate high detail reality model of the bridge that could be easily used by project stakeholders for planning of works.

Diospatial developed an aerial based capture methodology of the above and below deck elements. Nearly 13,000 high resolution images were captured and then processed in photogrammetry software, ContextCapture, to produce a 3D model of the entire structure. In addition to the 3D model, a photogrammetry point cloud and orthophotos were produced.

The 3D model reduced the reliance on rail possessions by removing the need for site visits—instead moving planning workflows to the digital space.

A survey control network was established to check and verify the geolocation and scale accuracy of the model.

The level of detail was so that project stakeholders could zoom in and complete a close visual inspection of the structure. This enabled consulting engineers to plan maintenance works and complete refurbishment designs without the need to visit the site during possession periods. It also provided access to hard to reach areas like the under deck and top of the bridge structure without the need for working at heights.

The final 3D reality model was hosted on a web-based Digital Twin platform, Pointerra. This allowed project stakeholders to visualize and collaborate on the 3D model without the need for specialist software or powerful computing hardware.